The argon is then pumped out, and the device is backfilled with nitrogen through a small-diameter filling hole. Prior to introducing the nitrogen, the device is laser welded in argon and placed outside the glovebox.

Devices containing nitrogen are therefore designed with a filling hole. However, seam-sealing titanium by means of laser welding is not possible in a nitrogen atmosphere, because it will generate hard and brittle titanium nitrides. Argon has a lower ionization potential and can cause internal sparking, whereas Nitrogen is the best gas for ensuring that the internal ionization potential is at the desired level. For devices, such as defibrillators which work with a much higher internal voltage, dry nitrogen is the most suitable gas for the internal atmosphere. Laser welding of devices containing nitrogen is more difficult. This gas atmosphere will be the same on the outside and the inside of the device. Laser welding of such devices is therefore relatively simple because the pacemaker can be entirely hermetically sealed in a glovebox system containing argon or a mix of argon-helium. A percentage of helium is commonly added to facilitate the detection of leaks in subsequent product testing. Argon is also suitable for long-term proper functioning of the device. When sealing titanium shells, not only is the hermeticity of the package important, but also the specified internal atmosphere of the welded device must be guaranteed because it will be permanently contained within the device.įor pacemakers, a dry argon atmosphere is preferred, allowing the titanium to be laser welded in an inert atmosphere.

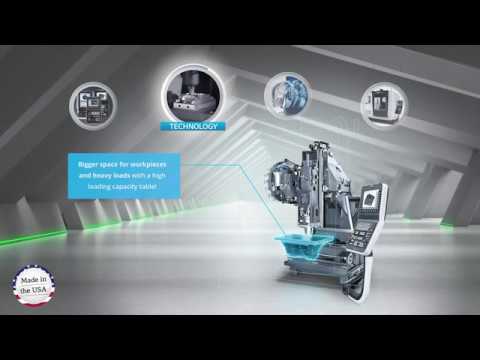

The system required for this pre-tacking is known as a laser pre-tacker. A continuous wave (CW) laser isn’t used to avoid transferring too much heat inside the device.īefore the seam sealing can take place, the two shells must be positioned, clamped and pre-tacked with small laser welds for a temporary or green strength fixation. The closing of the titanium shells has traditionally been performed by seam sealing with Pulsed Nd-YAG lasers. The number of welds varies according to layout of the device, but a single infusion pump, for example, can require 40 different welds. In addition, laser welding is also used to hermetically seal internal components of more complex devices, such as pumps, pressurized gas cylinders and fluid containers. These joints are often referred to as “helium leak tight,” meaning they will pass a leak test using helium gas. While many of the internal components of MIDs can be joined by soldering, brazing, or welding, the entire device is often packaged in two titanium parts (shells), with laser welding serving as the preferred method for hermetically sealing the two shells. Laser welding plays a critical role in the manufacturing of MIDs. NHX 8000 2nd Gen, ALX 2500, ALX 2000 and CMX 1100 V.Īutomation – Rotary Pallet Storage (RPS), Compact Pallet Pool (CPP) and Linear Pallet Pool (LPP) – NHX, Gantry – ALX and MATRIS – CMX V.ĭigitization – my DMG MORI, your customer portal, an online service manager which allows 24/7 access to service, machine documents, and Messenger, DMG MORI’s machine monitoring platform.Ĭustomers are encouraged to work with their local DMG MORI USA ASM to schedule a visit to the new, official DMG MORI Manufacturing USA production plant in Davis. Technology – NHX 4000 3rd Gen, NHX 5000 3rd Gen, NHX 5500 2nd Gen, NHX 6300 2nd Gen, “In order to continue to provide the cutting-edge solutions that we are so proud of, a restructure and an investment was needed.”ĭMM local production of technology, automation, and digitization solutions includes: “Investing in DMG MORI Manufacturing USA’s growth was essential and now enables the production of future innovations,” says Kazutoyo Moriguchi, president DMG MORI Manufacturing USA Inc. With the near $1 million investment, DMM has enhanced their production with future growth goals in mind to provide innovative solutions to customers.

Dmg mori cmx 1100 v software#

location includes horizontal milling technology, automation, and DMG MORI’s Software Technology Solutions providing digitization solutions.ĭMM has consolidated all production without eliminating any capabilities from their previous location. Production efficiency has been increased at DMG MORI Manufacturing USA’s (DMM) new location in Davis, California, enhancing manufacturing capabilities by investing in new equipment while consolidating production.

0 kommentar(er)

0 kommentar(er)